Jakob Olrik, CTO of Attensys, is implementing a wireless sensor system monitoring the heating infrastructure in a large office building in central Copenhagen, using NeoMesh for robust and flexible connectivity.

Attensys is based in Copenhagen and Berlin and specializes in IoT solutions, among other things using wireless sensor networks for different application areas.

Jakob Olrik explains:

– We find cases where it makes sense to collect data that can help our customers run a smoother operation and save money. And we help them find the reasons for something not working as it is supposed to, like in this case, where we monitor the heating system in an office building. It is a three-storey office building from 1968 with a heating system converted from steam to public district heating some years ago. It is quite large with about 30 small offices on each floor, and it has a basement area as well. There are about 100 radiators on each floor.

Targeting the correct temperature drop

Jakob Olrik has chosen NeoMesh for this project, as it gives him the flexibility and ease-of-use needed. Sensors can be deployed anywhere in the building, with the network nodes forming a wireless infrastructure automatically. If the network needs to be altered and nodes redistributed that is handled automatically as well.

– The big issue here is that we need to achieve the correct temperature drop in the system. To secure energy efficiency the district heating company requires the hot water that goes into the building’s heating system to have cooled down to a certain level upon re-entering the district heating system. Right now it is too hot, and if the water coming from your building is warmer than average you have to pay extra. If it is cooler it is the other way around: you can collect reward money from the district heating company. So there is a lot of money to be saved, if you can get as much as possible out of the hot heating water.

– To achieve as much heating efficiency as possible we need to understand how such a rather old building reacts to changing weather, wind etc., and that is quite interesting. One side of the building can be cold with people in the offices freezing, while on the other side of the building everything is perfect.

Plumbers gave up

– The plumbers maintaining the heating system spent a lot of time trying to find out what was wrong, but had to give up. They said to us they needed sensor data to get a detailed overview of the system before they could solve the problem. We have deployed such a system, and we like to think of it as a debug tool for heating systems.

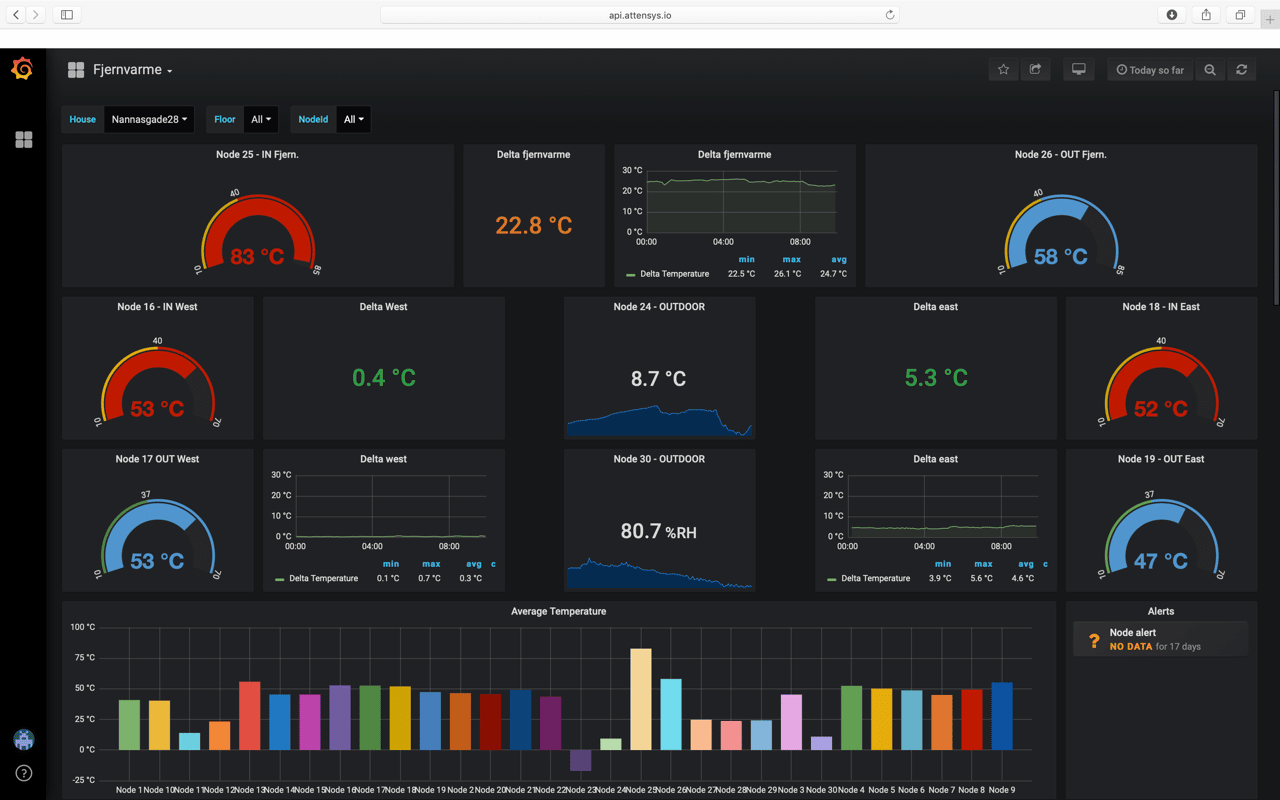

– The network consists of around 50 sensors. On each floor there are eight sensors measuring the main water streams, 32 in all. On top of that the system contains a number of temperature sensors in rooms that are known to have problems. To collect outside weather data we have placed sensors on each side of the building measuring temperature and humidity. Also, we pick up data from the local weather authorities.

Easy to deploy

– Due to the design of NeoMesh, the sensors are easy to deploy. That is one of the strongpoints of the technology: You just put in the sensors and the network finds the connections by itself. Another important advantage of NeoMesh is that we basically can use the same sensor everywhere. We just deploy it in different ways. And because of the clever design we can use one board for everything.

– Another thing is, that we need to change position of the sensors from time to time, to examine different parts of the heating infrastructure. With NeoMesh we can do that without much effort. The network adjusts automatically to change, and the nodes connect to each other by themselves. If we discover that a node is out of reach, due to walls or other kinds of obstacles, we just place an extra node nearby to establish the connection.

– The sensors come in different sizes to fit the size of the tube they are mounted on, and they come with a zip-tie for easy mounting. They have an antenna protected with a label to keep it straight to avoid touching metal, which would change the transmission characteristics. And although it is quite a large building we only need one gateway. If we encounter connectivity problems in some parts of the building we just put in an extra sensor and the network fixes itself.

The right balance

– We are now collecting data to see how we can tweak the system to work more efficiently. Each floor has two circuits that you can control separately, and basically the whole engineering trick is to find out what we can do to optimize these circuits. The trick is to find the right balance. You want as little water as possible flowing through the system while getting as much heating out of it as possible.

– We are collecting data and analysing it to see what we can learn from it. It is very much a trial-and-error thing: We change the setup of the heating system and then analyse the measurements to see the effect. We’ve built a nice dashboard where we can access the data and look at it over time, e.g. to see the effect of cold weather, strong winds and such.

– The most important thing right now is to learn about the dynamics of this system. As it is an older system it has been adapted to district heating. So we need to understand the dynamics of the building from the sensor data and build on that to find out which measures we need to take to optimize.

First-aid kit for plumbers

According to Jakob Olrik every building is different with its own characteristics. And working together with plumbers and other building maintenance people has made him realize that often you need a lot of data to get a proper understanding of a specific building. That has given him an idea:

– Plumbers need a mobile debug tool for complex heating systems. Think of it as a first-aid kit. If they are called out to look at a heating system that does not work properly, they can take with them a suitcase with sensors and zip-tie them to pipes or wherever else it is relevant. The sensors connect automatically to each other to form a small monitoring network that connects to the cloud and collects data over a week or two. Then the plumbers return, remove the sensors and the gateway, go home and look at the data to find out what to do and where to adjust the system, maybe fix a broken valve or whatever is needed.